Since the introduction of flash media, the technology is constantly changing to the point where it is very rare for us to encounter the same thing twice. We just finished up a project that looked to be a standard in and out project, but wound up to be considerably more complicated than a typical case.

When initially assessed, our team noted that it was a typical TSOP48 NAND chip connected to a USB thumb drive with a common PS2233 controller. Such cases are usually in and out within a few business days. So, we quoted the client and were given the go ahead to proceed.

When we removed the NAND chip and took a closer look, we discovered that it actually has 56 pins, like a TSOP56 chip, but the 8 outer pins were cut off, allowing it to interface with the TSOP48 connectors on the USB thumb drive. However, when we tried to interface the chip as a TSOP48, it would not fit in our TSOP48 reader because it was too wide, yet it was too long to fit in a TSOP56 reader.

We went so far as to connect it to a TSOP48 spot on our power board, but although it looked right, the pinout wasn’t even close to matching, which left us scrambling to come up with a custom solution.

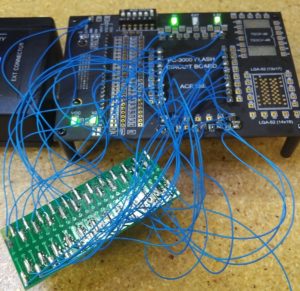

We ended up soldering the TSOP56 NAND chip to a basic TSOP48 board which would allow us to more easily manually wire each pin to the appropriate channel on our circuit board, allowing us to finally interface with the two channel NAND chip. Special thanks to Colonel Chappy on the Flash Extractor forum for posting a pinout.

Now that we were able to secure two 4GB dumps from the 8GB NAND chip, we had to then correct sector reads with ECC, following by a process to figure out the correct mix used to unscrable the bits into a healthy file structure and files. This threw us for a bit of a loop, as we were able to use typical PS2233 mixes to get a full clean file structure, but the files themselves kept coming up scrambled. With the some quick thinking by a team member at Ace Laboratory, our mistake of expecting the mix to be similar to other PS2233 controllers was corrected and we were able to get a 100% clean recovery.

Although most chip-off NAND data recovery projects aren’t quite this complex, they are almost always unique situations which require significant amounts of time and equipment in order to successfully recover the data.